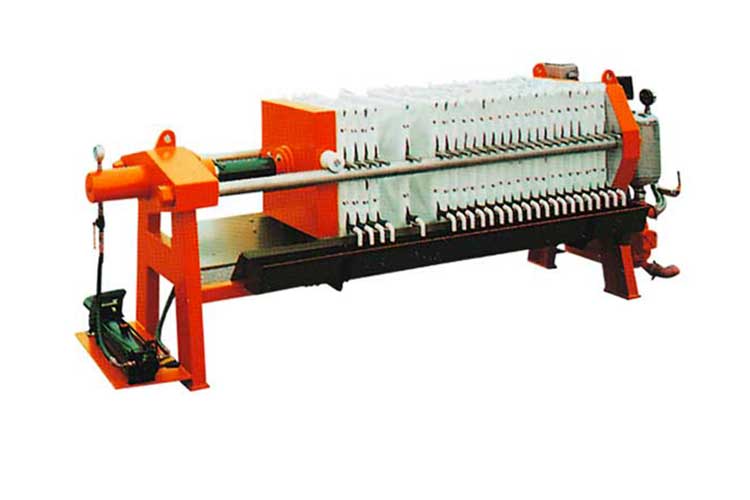

Manual Filter Presses

F500 S-IP-M Manual Filter Presses

The F500 filter press is the smallest in the series with manual plate movement and is built in three versions.

F600M Manual Filter Presses

The F600M filter press with manual plate movement consists of the following units:

F800M Manual Filter Presses

The F800M filter press with manual plate movement consists of the following units: