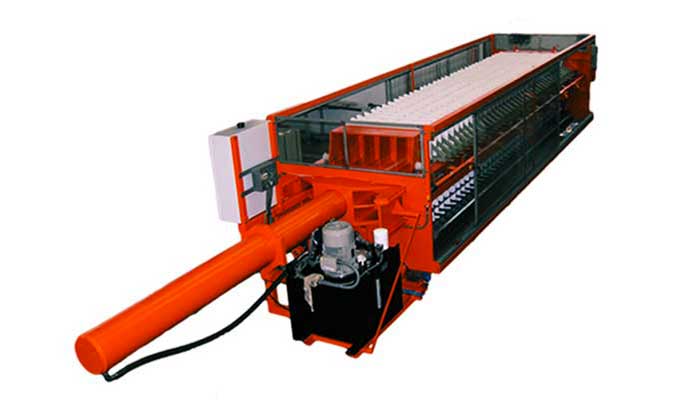

Simultaneous Opening Filter Presses

F500AS

Simultaneous Opening

Filter Presses

In addition to the production of traditional manual and semi-automatic filter presses, FILTRI FAZZINI offers a series of simultaneous discharge filter presses, with fully automatic cycle, for the dewatering of sludge with a high degree of filterability, in particular sludge from glassworks, quarries, foundries, galvanic-metallurgical industries, ceramic industries and from granite, marble and aggregate processing.

F600AS

Simultaneous Opening

Filter Presses

In addition to the production of traditional manual and semi-automatic filter presses, FILTRI FAZZINI offers a series of simultaneous discharge filter presses, with fully automatic cycle, for the dewatering of sludge with a high degree of filterability, in particular sludge from glassworks, quarries, foundries, galvanic-metallurgical industries, ceramic industries and from granite, marble and aggregate processing.

F800AS

Simultaneous Opening

Filter Presses

In addition to the production of traditional manual and semi-automatic filter presses, FILTRI FAZZINI offers a series of simultaneous discharge filter presses, with fully automatic cycle, for the dewatering of sludge with a high degree of filterability, in particular sludge from glassworks, quarries, foundries, galvanic-metallurgical industries, ceramic industries and from granite, marble and aggregate processing.

F1000AS

Simultaneous Opening

Filter Presses

In addition to the production of traditional manual and semi-automatic filter presses, FILTRI FAZZINI offers a series of simultaneous discharge filter presses, with fully automatic cycle, for the dewatering of sludge with a high degree of filterability, in particular sludge from glassworks, quarries, foundries, galvanic-metallurgical industries, ceramic industries and from granite, marble and aggregate processing.

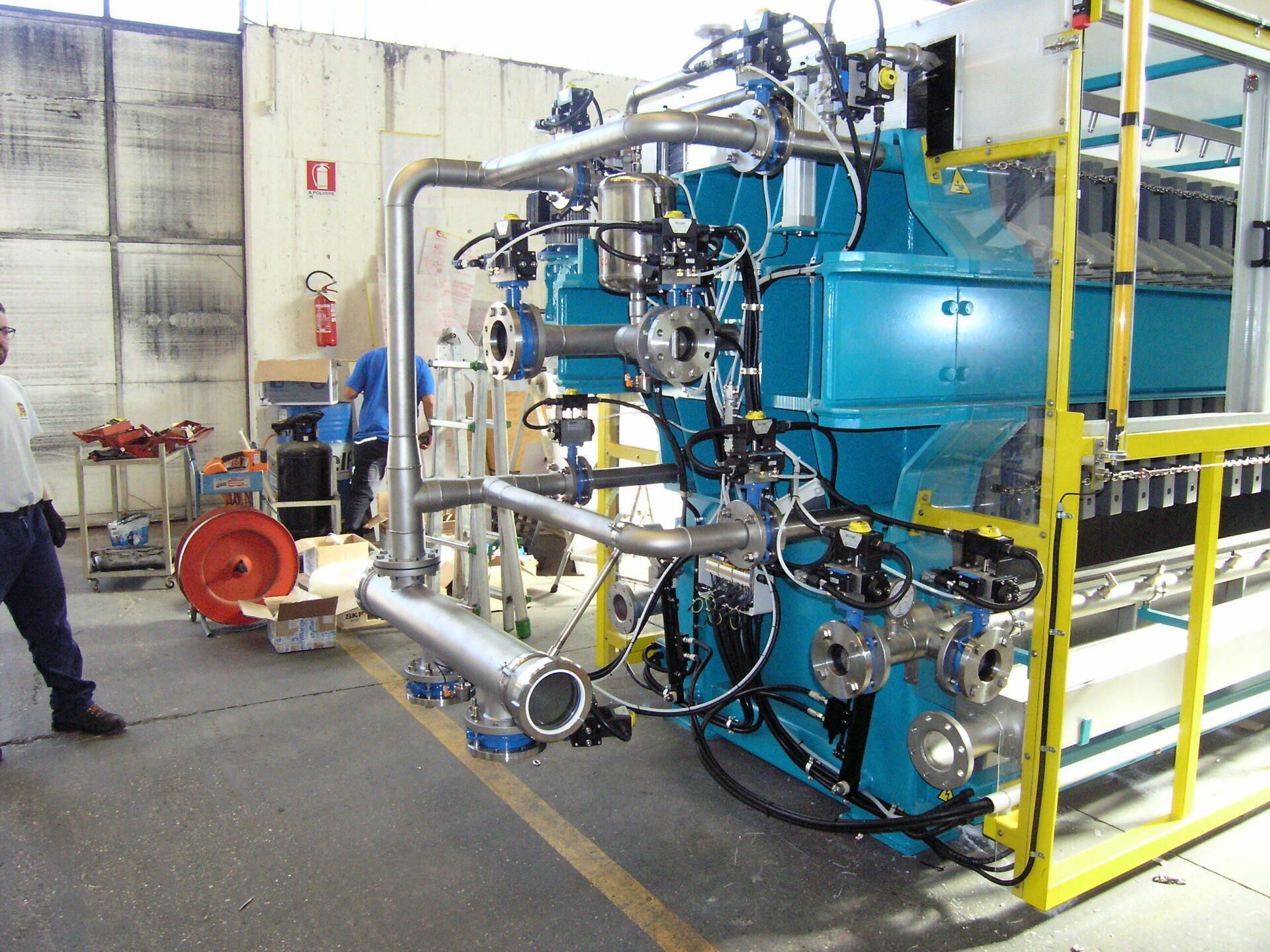

F1200AS

Simultaneous Opening

Filter Presses

In addition to the production of traditional manual and semi-automatic filter presses, FILTRI FAZZINI offers a series of simultaneous discharge filter presses, with fully automatic cycle, for the dewatering of sludge with a high degree of filterability, in particular sludge from glassworks, quarries, foundries, galvanic-metallurgical industries, ceramic industries and from granite, marble and aggregate processing.

F1500AS

Simultaneous Opening

Filter Presses

In addition to the production of traditional manual and semi-automatic filter presses, FILTRI FAZZINI offers a series of simultaneous discharge filter presses, with fully automatic cycle, for the dewatering of sludge with a high degree of filterability, in particular sludge from glassworks, quarries, foundries, galvanic-metallurgical industries, ceramic industries and from granite, marble and aggregate processing.